Chi è on-line

We have 3 guests onlineStatistiche

Content View Hits : 133432| QUALITY |

|

|

|

| Written by Administrator |

| Wednesday, 27 January 2010 19:28 |

|

The Perati Mario snc decided some years ago in a far-sighted to begin the path to the pursuit of quality ', beginning the path to certification, with the sole aim to reduce defects, increase customer satisfaction and re-production cycles, without the required certificates .

Today, after a hard work started in 2008, applying to all procedures provided by UNI 9001/2008, we felt the need 'to end ritch with obtaining certification, which represents for us a new starting point. Accordingly, in October 2009 we had an inspection by the entity CERMET, and with great satisfaction we have obtained the UNI EN ISO 9001:2008 on 27/11/2009.

The Perati Mario snc works on the following levels to ensure the quality 'of the final product:

Check-in acceptance of incoming materials by logging on cards

-Reports of sampling and approval to produce

Self-sheet during machining

-Traceability 'batch production for special security, or if requested by the customer

-Destructive analysis of welding controls and archiving of specimens

-Calibration of measuring instruments and control

- Analysis of welds and materials at laboratories

- Monitoring and recording the final on special cards.

Are also processed monthly indicators to monitor business costs, customer satisfaction, quality of suppliers Perati Mario snc, to always guarantee our customers the best value for money.

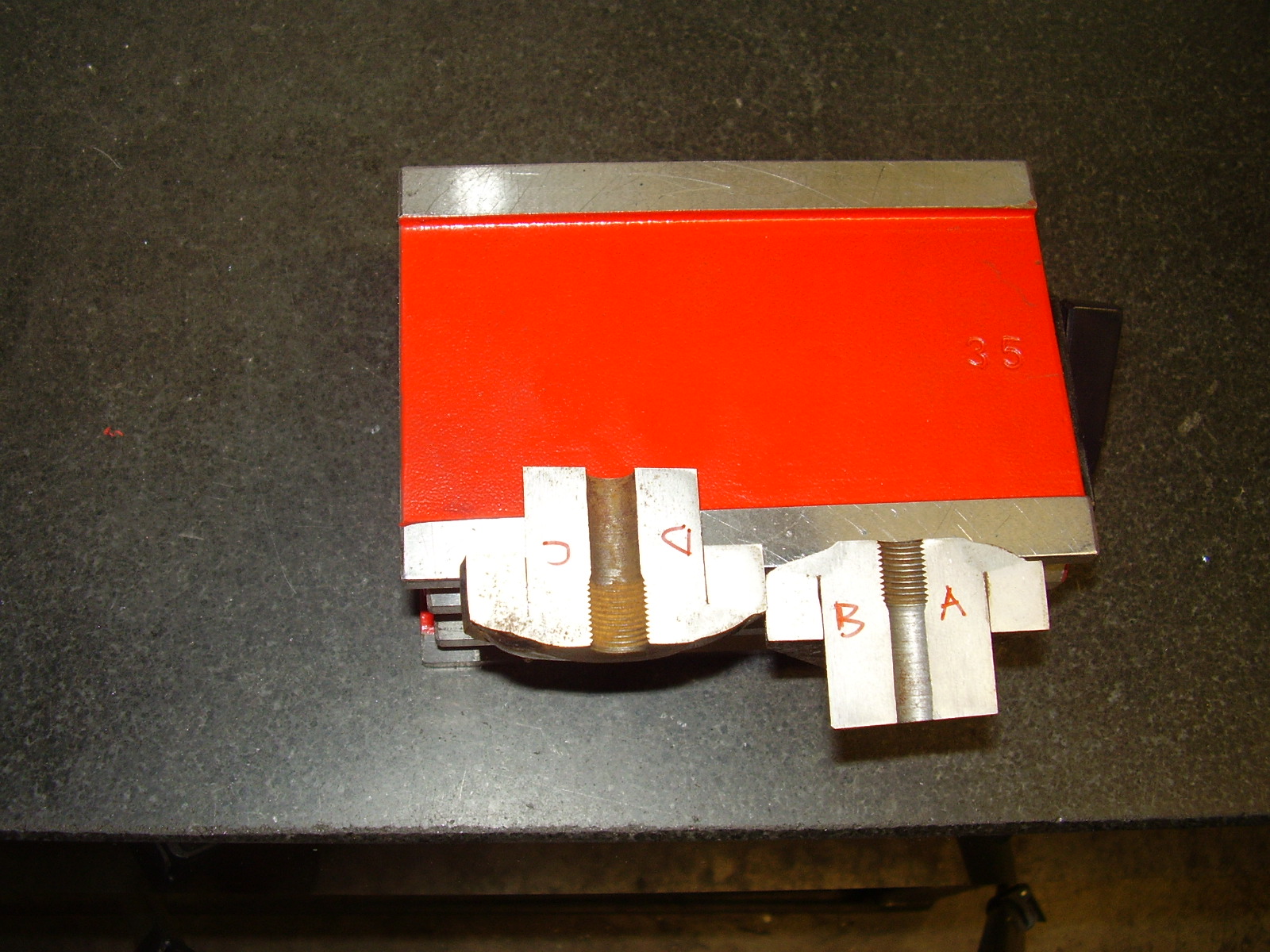

The image below and 'ple of a section of a tree to control the welding position of welding cycle and storage of test |

| Last Updated on Wednesday, 14 December 2011 16:18 |